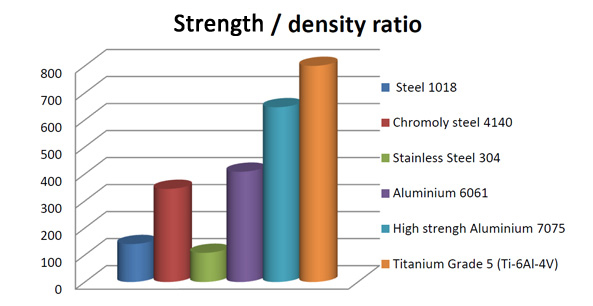

Titanium is naturally lighter than stainless steel, but this results in less material required to support the exhaust system. Titanium has the highest strength-to-density ratio of any metallic element on the periodic table (about 60% less dense compared to steel), attesting to its benefits. Therefore, the wall thickness of titanium tube can be thinner while giving the same if not more strength to the exhaust. The less weight on your vehicle the more it will improve your lap times, fuel economy, braking, handling and acceleration.

Towards the left and on top are pictures of a RathGibson Stainless 3" tubing. Bottom right, is our ThaiTanium 3" tubing. The stainless is 4ft in length with a weight of 7.6 lb. Our titanium is 4.5ft total with a rounded up weight of 3.6 lb. (scale is in kg). When comparing titanium tubing to stainless steel tubing, you're saving a little over 45% in weight.

Titanium has a low modulus of elasticity, which means that titanium is not as flexible as stainless steel, but returns to its original shape after bending, resulting in its importance to shape memory alloys. Since titanium is lighter it is less susceptible to damage when dropped accidentally. CPGrade2 possesses good weldability, strength, ductility and formability.

Titanium has a higher specific strength than stainless steel. However, since titanium is less dense, it becomes the preferred choice among many professionals. It performs well in all environments. A good example would be your exhaust system; no loss in strength at temperatures as low as -190C. Conversely, titanium can withstand temperatures up to 600C. We do not believe your exhaust will be generating enough heat to exceed that limit. In the eyes of ThaiTanium, titanium is the ideal metal!

The corrosion resistance of titanium is well documented. Whenever fresh titanium is exposed to the atmosphere or to any environment containing oxygen, it immediately acquires a thin tenacious film of oxide. The presence of this surface film that confers on the material its excellent corrosion resistance. Provided that sufficient oxygen is present, the film is self-healing and re-forms almost at once if mechanically damaged. Natural scraps, bumps and scratches from the road is no scare to titanium’s oxide film.

Titanium is a very reactive metal that shows remarkable corrosion resistance in oxidizing acid environments by virtue of a passive oxide film. The oxide film formed on titanium is more protective than that on stainless steel, and it often performs well in media that can cause pitting and crevice corrosion. This means titanium performs well even in the saltiest road conditions and heavy rain without compromising its integrity! Place confident in our CPGrade2 titanium for it will not oxidize in any element!